a wide range of mechanical tests

Among the many environmental tests required during the qualification phase of your products, VITESS testing center covers a wide range of mechanical tests that can be divided in multiple categories:

– Vibrations:

– 1 and 2 axis vibrations, with sinusoidal, random, sine on random, random on random profiles

– Low, medium and high frequencies vibrations thanks to our hydraulic and electrodynamic testing means up to 160 kN

– Vibrations at standard laboratory conditions or controled temperature (static or heat/cold cycles)

– Transport simulation

– Windmilling

– Shocks: 1/2 sine, sawtooth peak, trapezoid profiles, SRS on shakers or shock units

– Constant centrifugal acceleration thanks to our multiple centrifuges up to 10-meter diameter

– Free fall

– Pitch, roll, trim, heeling, yaw

– Tensile, compression, force, endurance

– Static and dynamic stiffness

Our testing center is equipped with many hydraulic actuators and electrodynamic shakers of different characteristics (displacement, acceleration, velocity) within a force range from a few kN to our most powerful shaker of 160 kN. This specific equipment pool allows us to adapt to all size and weight of test specimens and to meet at best your needs.

Contact us for all your vibrations, shocks, constant centrifugal acceleration… test requests.

You will find below a more exhaustive or our testing means.

We are also able to design and manufacture the mechanical interfaces in order to link your test specimens to our testing means.

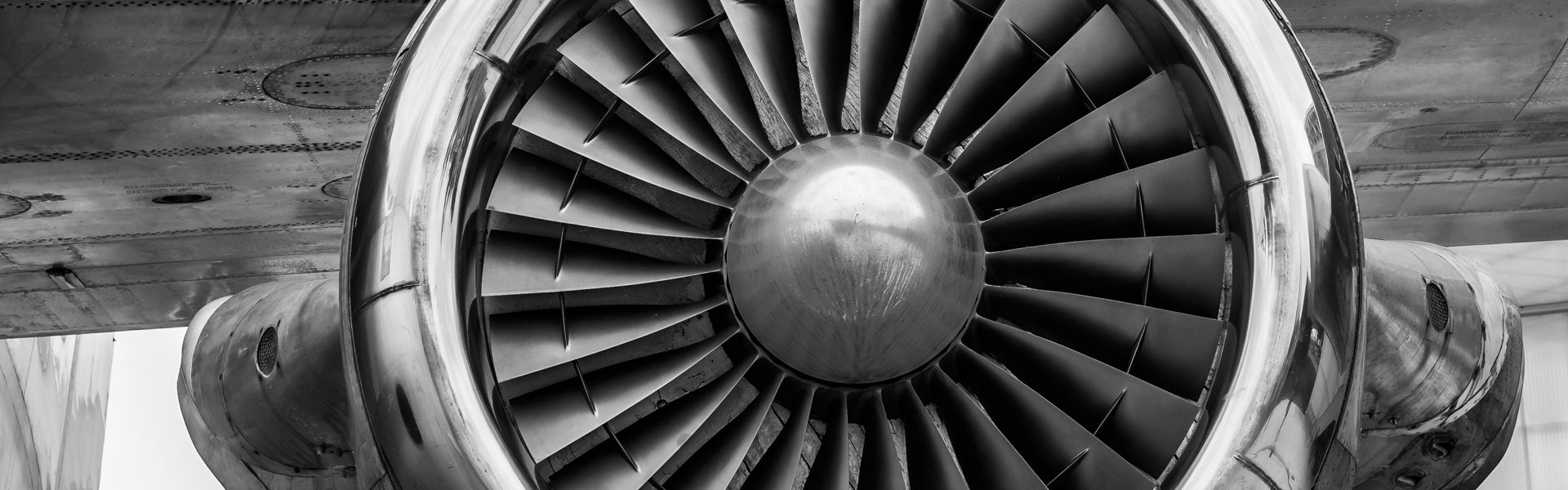

We work every day for many cutting-edge industries such as the aeronautic, defense, space, automotive, railway, marine, but also nuclear, energy, textile…

The mechanical tests in these industries are regulated by standards and our testing center strictly follow them:

– Field standards:

- – CEI 60068-2-6 sinusoidal vibrations

- – CEI 60068-2-27 / CEI 60068-2-29 Shocks

- – CEI 60068-2-64 random vibrations

– Standards linked to industries :

- – RTCA DO-160 / EUROCAE ED-14

- – MIL-STD-810

- – STANAG 4370 AECTP 400

- – DEF STAN

- – CEI 61373

- – ISO 16750-3

– Standards form European, American, Asian manufacturers

VITESS is also able to adapt to specific requirements to perform special or not standard tests. We study every test specification in order to best answer the multiple needs and create the ideal testing mean.

The flexibility of our testing center also allows us to perform combined vibrations, temperature and fluid circulation tests.

Here are listed the main testing means we have in order to execute your mechanical tests:

- – 12 shakers covering a range from a few Newtons to 160 kN, equipped with horizontal tables with TEAM bearings in T and V shape of a size of 300 to 3000 mm (maximum payload = 2 tons; maximum acceleration = 100 g; maximum speed = 2 m/s; maximum displacement = 3 inches)

- – 6 hydraulic shakers low frequency (maximum force = 150 kN; maximum displacement = 250 mm)

- – Independent or steered simultaneously for multi-movement pneumatic cylinders

- – Centrifuge of varying diameter from 0.2 to 10 m (adjustable acceleration from 1 to 30 000 g)

- – 5 traction and compression (maximum force = 500 kN)

- – Force / movement bench

- – 3 mechanical shock units, vertical and horizontal

- – 2 Sloch testing benches

- – Free fall bench

- – Dynamic impact testing bench

- – Multi-axes maneuver bench